To DIY white marble flooring will add beauty and elegance to a your home or your hotel. Installing marble floor tile is not that easy process anyway it can be done on your own if you have enough patience and care.

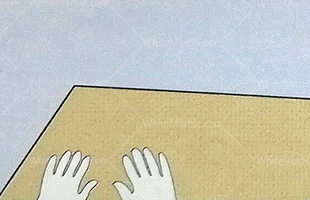

Gloves will protect your hands, eye protection will protect your eyes while a facemask will protect your lungs when install the white marble tiles.

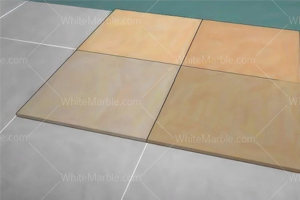

White Marble is soft tile and easily cracking if it is not installed on the same level surface, so we have to make sure the floor is level.

Draw a pattern to scale on the paper using the real area dimensions and sizes of the white marble tiles.

Measure each wall of the center by using a pencil and then have a chalk to hold it to each end then work out the center of the floor.

This will help you to know where the white marble tile s should go.

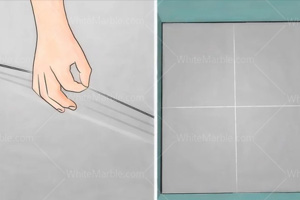

Place the white marble tile s within the grid you have made.

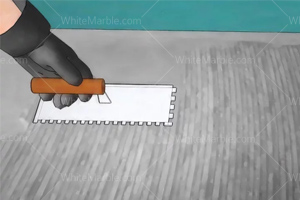

Make sure you wear the heavy-duty work glove and sure to wear heavy-duty work gloves and make sure the adhesive is thick enough that you can use the notched edges of the trowel to make grooves in the adhesive.

After applying the adhesive, lay the white marble tile s on the top of it within 10 minutes.

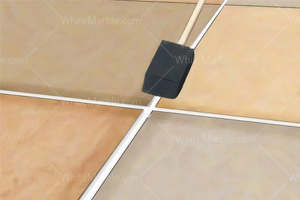

Use 1/8” (saying 3mm) white marble tile spacers to create the correct spaces between each tiles make sure they are in the straight line.

Check all white marble tile s to ensure that they are even on the same level. Find a length of wood and put it on tops of white marble tile s, using a hammer to tap the wood down very lightly until all tiles are on the same level.

Electric mix machine, mixing barrel, brush, spade, batch board, etc.

Mix the adhesive liquid and the reinforce powders, to match with the specified ratio in weight , stirring evenly with a electric agitator, and let stand for about 5 minutes.

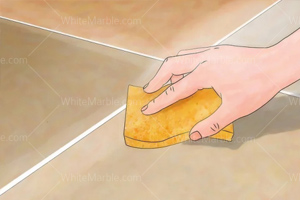

Clean the dust and dirt from the back of the white marble with a brush and spade.

Scrape the resin back mesh layer on the back, repairing the cracks with resin adhesive if needed, apply "dispensing method" and clean up the overflow resin around the cracks.

Place the marble on the bracket and press the pre-cut mesh on the stone surface.

Pour an appropriate amount of mixed adhesive onto the mesh, and scrape the slurry with a batch of plates to evenly cover the entire mesh cloth, and the thickness is controlled to about 0.8 mm to 1.0mm.

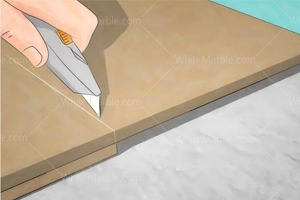

The slurry overflowing on the four sides of the stone is cleaned with a blade or a utility knife when it starts to dry.

After the adhesive layer is dry (the touch surface is not sticky), the marble tile can be collected. Cutting, grinding and other operations can be carried out only after 48 hours of maintenance under natural conditions.

During transportation and installation, white marble should be protected from rolling or colliding, to avoid the slab cracking or damage. When stacking outdoors, tarpaulin should be covered to prevent rain from getting wet or get stain.

The flatness and strength of the construction foundation should meet the requirements. Find the benchmark through the elastic line on the ground base.

Remove dirt and ash from the ground base and the back of stone.

Electric mixer, toothed scraper, rubber hammer, horizontal ruler, brush, etc.

Mix the liquid and powder of stone glue according to the specified weight ratio, stir evenly with electric agitator, and stand still for about 5 minutes. The stirred slurry should be used up in 2 hours.

Use a brush to spread the stirred stone glue evenly on the back of the stone. Cannot be missed any part of stone back. Naturally dried then be ready for use. The adhesive construction environment temperature is 5~35°C.

Stir the stone binder and water in a specified weight ratio with electric agitator. Leave it for 5~10 minutes, then stir it for a while. The stirred slurry should be used up within 2 hours.

The stirred stone binder is scraped on the base layer by a toothed blade, and the toothed strip is pulled out. If the base surface is too flat, the binder can be scraped on both the base layer and the back side of the stone.

Place the stone on the binder and the sticking construction environment temperature is 5~35°C.

Roll and tap with a wooden hammer or rubber hammer to achieve a flatness; stay joint between stone.

The finished product is open protected, and within 1 day after the bonding construction is completed, the stone should not be stressed, in order not to affect the quality of the sticking.

After 7 days of sticking construction, joint filling construction is carried out. Do not expose to rain or water for 48 hours after the filling construction is completed.

HOW CAN WE HELP?

Any Requests Please Contact Info@WhiteMarble.com, Thank You!